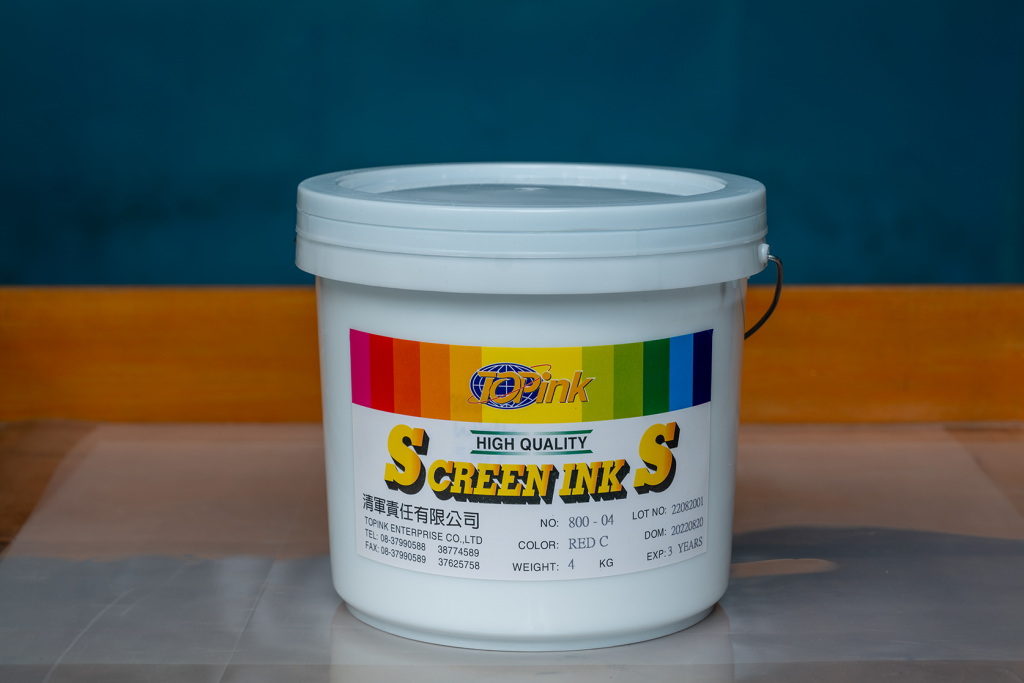

plastic transfer ink

- 800 ink Suitable for transfer printing on acrylic, ABS, PS, PC, plastic products, and special ink for plastic transfer printing.

- Ink characteristics: This ink is non-toxic, low-odor, light-resistant, high-brightness, scratch-resistant, abrasion-resistant, and alcohol-resistant.

Rubber vulcanization transfer ink

- 8061 series ink is suitable for rubber transfer printing ink

- Ink characteristics: This series of inks are suitable for vulcanized transfer printing on various rubbers such as basketballs, tires, and belts. The ink is non-toxic, low-odor, highly elastic, temperature-resistant, weather-resistant, does not discolor, and has excellent printing suitability.

- Production process: First add 3% of the total amount of vulcanizing additive and diluting solvent to the ink and mix it evenly. Then use screen printing to print the ink on a 12um PET film (non-discharge treated surface). After the ink is completely dry, stick it on On the transferred raw rubber,

- After vulcanization by vulcanization molding equipment, the raw rubber and transfer pattern are vulcanized on the rubber at the same time at a temperature of about 130°C-150°C and a time of about 5-10 minutes (it may vary due to product requirements and differences in raw rubber materials from each manufacturer) ), just tear off the PET film after the vulcanization is completed.

Cloth transfer ink

- 806 transfer ink is a special ink suitable for transfer printing on various types of cloth.

- Ink characteristics: This series of inks are suitable for use on various types of fabrics, especially on highly elastic fabrics. It has extremely high elasticity and resilience, and can also reach a very high level in terms of water resistance.

- This series of inks are non-toxic, low-odor, highly elastic, and have excellent printability.

- Process: 806 series ink is printed on the PET release film, and then printed with a special hot melt adhesive for cloth transfer. After it is completely dry, it is placed on the transferred cloth and passed through the transfer machine at a temperature of about 130℃-150℃ ℃, time about 10-15 seconds, pressure 3-4kg/cm²